|

Ecofilt Mikrofilter (Part of the articel COST REDUCTION IN TECHNOLOGY FOR GAS TRANSPORTATION AND STORAGE USING ECOFILT MIKROFILTER which was presented in Belgrad during the GAS 2004 Conference) What does this trademark or name stand for? Ecofilt Mikrofilter is a candle shaped cascade or multiphase filter. As shown on Fig. 5, it is a candle shaped filter made of stainless steel. Owing to its design, this filter is highly resists to and allows great pressure differences (deltap) of up to several bars. Filtering surface is cylinder - candle - shaped wrapped around the base core. The wrapping has one layer, therefore the free surface of the filter is set with high precision (even 98%). Thanks to the wrapping the shape and size of the slits are also of high precision, which is between 95-98%. This property gives highly reliable and precise separation of filtering surfaces. Micron-gauge wire wrapped around the base core is also made of stainless steel. Based on our experience, we can say that we have designed a robust candle shaped filter core with low initial resistance, which can stand great strains, and has a long operating life of up to 10-15 years.

Production technology in petroleum industry allows us also to manufacture and/or alter certain elements of the filter base core according to the user's specific requests. As a result, it is now possible to replace existing filter cores existing housings. The possibility to change the filtering parameters allows us to maintain the existing filter surrounding. This leads to significant investment cost reduction.

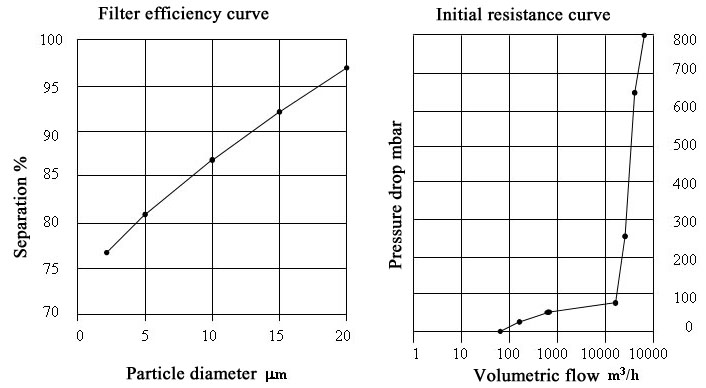

Fig. 6 Prefilter under a microscope Prefilter can be single or multilayered, which depends on the targeted filtering process goal. By its adequate positioning and calibration, it can filtrate and storage large quantities of impurity. Such filters then simplify and increase maintenance level, since they only require replacement of the deep bed filter. Our experience has proved that the prefilters can easily be washed (in suitable solvent); then reused, and this process can be repeated several times. These particular types of cascade filters can be applied to industries that operate in high temperatures. With theaEcofilt Mikrofilter such influenst, as gas, steam, liquids, emulsion, etc. can be cleaned with selected methods. This filter is highly precise, has a long operating life, gives the user the possibility to plan its replacement, and has a remarkable filtering efficiency to 2 Ám.

Fig. 7 Filter unit Cascade filters can be cleaned in a few ways, which are very simple, unless the filtered medium contains sticky solids.

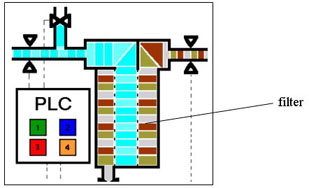

Fig. 8 Filter unit for gas injection into underground strorage Ecofilt Mikrofilter can be supplied with various control instruments, such as flowmeter, gauge, velocity meter, etc. All information registered by control instruments can be gathered into a computer data base. With the support of control instruments there is only a step towards complete process automation. Based on required technical characteristics of the instruments, Ecofilt Mikrofilter allows filtering process management from PC, by applying PLC. PLC can make daily reports on filtering process. To analyze and gather instrument information a PLC can be upgraded with such software that would include control, correction and training.

Fig. 9 PLC Ecofilt Mikrofilter supported filtering unit can be operated, controlled and cleaned using PLC control. All electronic devices are adapted to the existing electronic surrounding and processes, with which complete accord and communication is established. In SummaryaEcofilt Mikrofilter

is a cascade candle shaped filter that adapts to existing

industrial processes; it is easy to design and calibrate,

does not require high maintenance, and eventually can be

automated. Robust construction of cake filter made of

stainless steel allows it to be applied to any industrial

environment where the following is required: Ecofilt Mikrofilter expands and allows the possibility to calculate and measure mechanical filtration without making additional stress to the medium, and the possibility to appley effective cleaning and flushing in both domestic and industrial environments to up to 2 Ám. Reference of its operation can be seen in Hungary and Serbia and Mintenegro. |