COST REDUCTION IN TECHNOLOGY

FOR GAS TRANSPORTATION AND STORAGE

USING

ECOFILT MIKROFILTERJános

KIRÁLY1, Róbert KOVAC2 and

László LIVO1

1- MARKETINFO, Hungary

2- HELIR, Serbia and Montenegro

Abstract:

aaThis work presents filter installation

suitable for mechanical filtering of natural and other

types of transported gas. Minimal

particle size can be less than 2 microns.

aaDuring the last decade Ecofilt Mikrofilter has proved its

applicability in underground gas storage, gas

transportation and

with other various users. Ecofilt Mikrofilter allows the user to

plan his filtering costs and to ensure maintenance costs

optimization in advance. The plans are feasible and

realistic, which have been proved by the experience of

its current users

in gas industry in Hungary and Serbia and Montenegro.

aaEcofilt Mikrofilter is a filtering

installation with working period of 10 years. Its ability

to perform strict particle filtering

derives from the very technology used for its make. The

filter's guaranteed layer and body are made of stainless

steel, which

gives the filter longevity and hardness (high deltap) and

makes it easy to clean and maintain.

aaThe filters can be installed into any

existing housing. In such cases the filters can take more

flow, the filtering is more

accurate, and the safety is also increased when compared

to the original construction. High permeability also

derives from

the technology. It allows for small initial resistance

(only a few millibars) and gives rather high tolerance to

impurities.

aaThe very possibility to plan ahead allows

the user to select the most suitable filtering

installation, which would also allow

the user to lower the initial investment costs as well as

the maintenance costs.

aaIn summary, the most important fact about

these filtering installations is that they have long

lifetime, require low initial and

low or insignificant maintenance costs, since they lead

to lower instument damage rate by protecting them. This

can be proved

by dramatic cost decrease.

aaThis work presents design,

construction/installation and application of the filters,

as well as the users' experience in use of them.

Key

words: filter, gas, costs, maintenance.

1.

Mechanical filtering - introduction

aaTo introduce mechanical filtering, let us

first see what it is about; an experiment would be a good

starting point. Take a full

glass of drinking water and pour the content to another

glass through filter paper (or through a serviette).

After the filter dried,

we can see that colour of the paper has changed. This

would indicate that the water had contained some elements

- impurities,

which remained on the filter paper. If we repeated

pouring several times, the filter would come to a point

where it could no

longer let the water flow through. Particles that had

kept on the filter formed an impregnable layer. If, on

the other hand, we

analysed the water at lab after each pouring, we would

see that it contained less and less impurities each time.

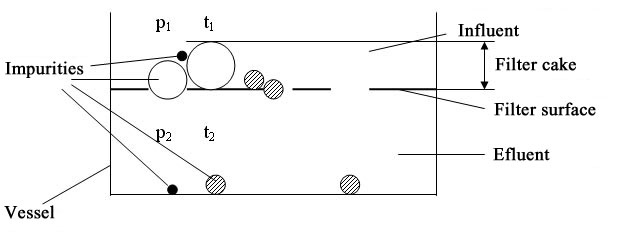

aaWhat is the explanation of this

phenomenon? On the filter paper surface a filter cake is

formed, which is made of impure

particles that are also part of the filtering process.

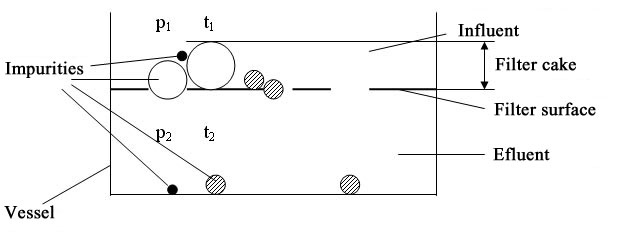

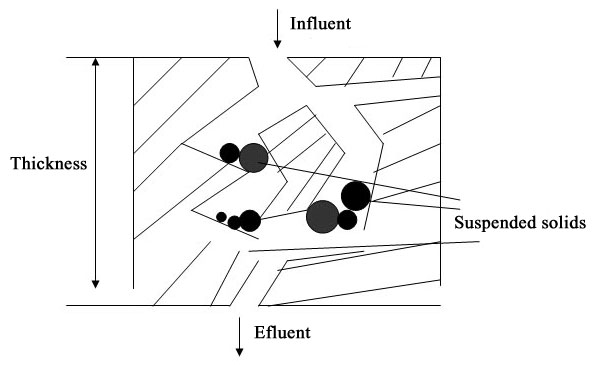

This leads to the conclusion shown in Figure 1.

Fig. 1

Mechanical filtering

aaThe experiment results gives us certain

knowledge: impurities can be found in both to be filtered

and has been filtered medium

(influent and efluent, respectively), but in different

contents. Another result is that the filter cake contains

impurities of different

size and shape.

aaIf we repeated the experiment with an

other filter type, for example we used a piece of cloth

instead of filter paper, the results

would also differ, first in time taken to filter the

water. To be more accurate, if the quantity of water was

different, so would be

the time of filtering. That would lead to the difference

in filter cake formed on the cloth. Taking all previous

results into

consideration, we can say that the quality and refinement

of filter are not the only factors that influence the

filtering results. To

keep the process under control we need to consider more

factors.

2.

Filtering characteristics

aaAnalyzing results of the previous

experiment, we can conclude that the most important

characteristic of a filter is its refinement,

which is determined by separation parameter. Its mark is

µm (micrometer = 0.001 mm). Other important parameters

are filtering

surface (or filtering area - square meter - m2)

and free light area (%).The free light area is a number

directly dependent on filter

quality. This number indicates the initial size of the

filter area through which a fluid can flow continually.

aaIt is now easy to conclude that over a

course of time the light area is reduced, owing to

formation of filter cake. On each side

of filter the allowed pressure difference (deltap) is

resenst, which is a significant property to have in mind

in filter manufacturing.

Filter data has great influence on fliter cake, its

thickness and filtering time.

aaApart from the parameters given above,

there are other equally important ones that should be

considered in designing filtering

technology: filter material, filtering fluid, medium

temperature, pH, electric conductivity, etc. Two aspects

allow optimal filtering

results:

aaaaaa) identification of an existing system

operation and possibility of improvement of filtering

technology based on laboratory

aaaaaaaanalyses,

aaaaab) well selected final goal of filtering

process and its results' confirmation in a lab.

3. Main types of mechanical filters

aaMechanical filters can be divided in two

main types. Surface filters are those

with flat surface, e.g. net, sift, or those of

certain geometric shapes, which surface can also be used

as filter (cylinder, cone, dome). These filters are

candle or plate

shaped, and filter cake is formed on the surface (Fig.

1).

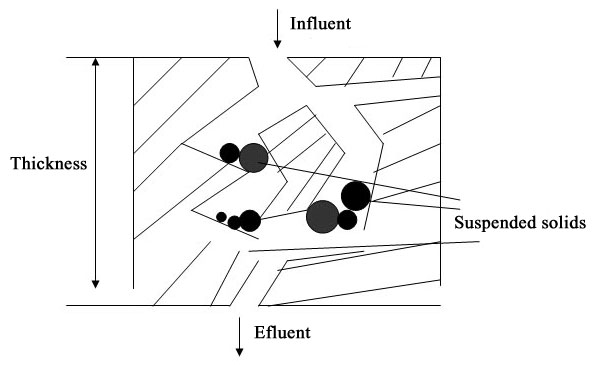

aaAnother type is the deep bed

filters, which spread into the third dimension.

The third direction is usually much smaller than

the other two.

aaOperation of the two filter types is

basically different. While the surface filter strictly

separates suspended solids from the

filtered fluid, the deep bed filter's separation can not

described with one dimension, only with thickness

territory.

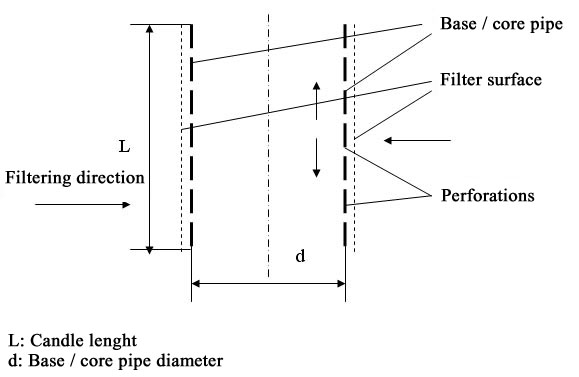

aaIn deep bed filters, there is no filter

cake formation; any changes are made in the third

direction, and they depend on how and

where certain granules are positioned; the granules then

flow through or are suspended in channels that are formed

during the

filtering process. The channels' dimensions are

influenced by design, material, geometry (diameter) and

permeable layre of the

deep bed filter (Fig. 2).

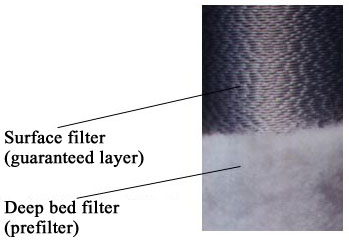

Fig. 2 Deep

bed filter with flowing channels.

4. ECOFILT Mikrofilteraa

aaThis filter construction is adapted to

existing technologies in gas production, transport and

storage. Its application allows a

simple way of requested level of gas separation and

purification. Pipeline solids, corrision products,

compressor oil, oil droplets

and oil fog can be filtered with Ecofilt Mikrofilter. By applying adequate

technology, liquid phase and mechanical impurities

can be separated from associated gas.

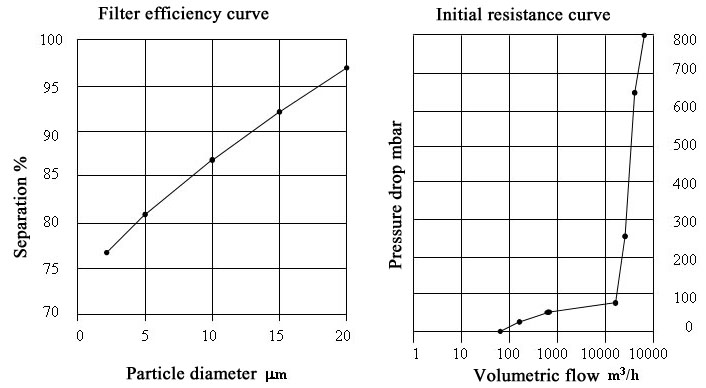

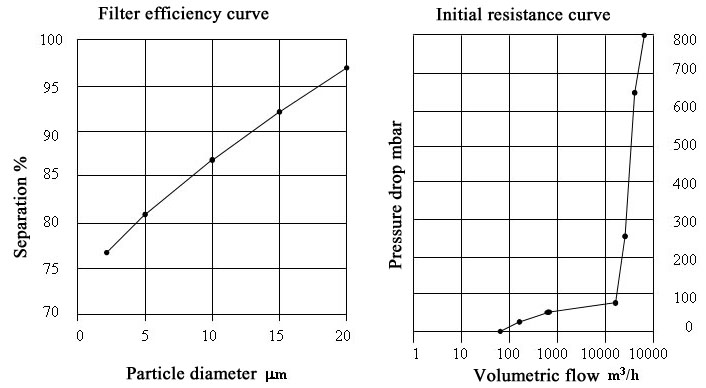

aaFiltering purity is 5 to 2 µm; filtering

accuracy is 95-98%; filter flow and pressure are

significant. Average initial resistance of

filter group is 0.1 bar.

aaThere is a significant advantage of Ecofilt Mikrofilter when compared to other

filters, and that is its operating lifetime of 10

years. In effect, this would mean that after cleaning,

this filter is not wasted, but returned to the system,

which, as a result,

minimizes maintenance costs. The user can plan the

maintenance cycles in advance, which makes it an input to

the system design.

Another advatage of Ecofilt Mikrofilter is that it can be installed

into existing systems to replace the existing filters,

and can even

be installed into existing housings.

aaA unique statement of our business

partners that have been using Ecofilt Mikrofilter is that it allows them to

achieve lower

costs of compressor repairs and significantly reduce

presence of impurities in the systems; Ecofilt Mikrofilter also allows for

better protection of test wells and layers. Its use can

also reduce overwork labour costs and chermical treatment

of wells.

4.1

Candle shaped filters - introduction

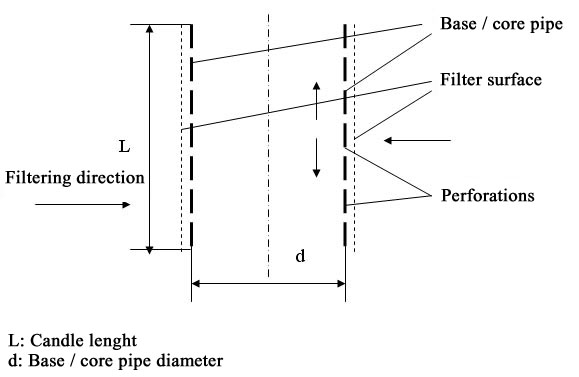

aaCandle shaped filters are widely used.

Its main advantage is easy installation, and another is a

relatively large filtering area on

a relatively small surface.

aaCandle or cylinder shaped filter core

serves as a base for spreading filter net - metal,

plastic, or cotton - or filter paper. The

filter core is determined by the user's design; its shape

is defined by the final goal that the user wishes to

achieve by the filtering

process.

aaThe usual candle shaped filter core is

shown in Fig. 3.

Fig. 3 Candle

shaped filter's principle

aaThe usual filter design allows for target

application and training. The L/d ratio affects the mode

of flow. Filtering quality, free

area, flitering fluid and other technical parameters have

significant effect on initial resistance, saturation time

and possibility of

cleaning.

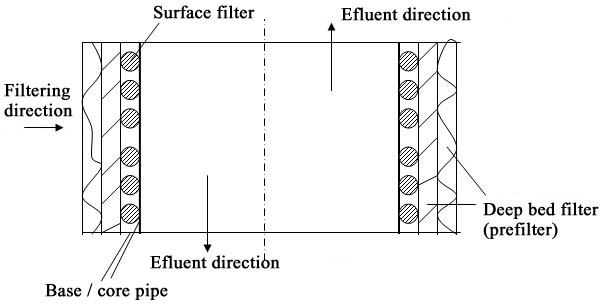

4.2

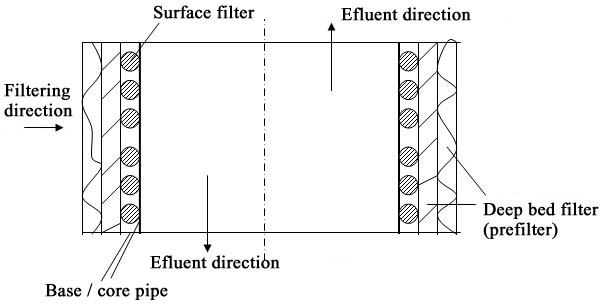

Cascade filter

aaFilter cores can easily be rearranged in

such shapes that would allow the filtering fluid to flow

through several filtering surfaces.

The surface filter can be supplemented also with deep bed

filter. This principle allows the user to design such

filtering systems

that would result in higher level of separation and solid

suspension from the filtering fluid.

aaOne of the most important characteristics

of cascade filters is the low initial resistance. Another

advantage is high deltap value,

wich can be achieved by a robust system consruction.

aaAn important point is to have a quality

surface system that would allow filtering fluid flow for

a lengthy period of time, which

would lead to conditions for a longer filter life cycle

before replacement and a good chance to flush the filter.

The following

Figure shows one candle shaped filter cascade type.

Fig. 4 Cascade

filter (3 stairs)

aaOf course the cascades are selected

according to previously conducted lab tests and requested

filtering quality. Figure 5

shows a scheme of a practically applied two-stairs

cascade filter, one surface and one deep bed filter

(prefilter).

Fig. 5 Ecofilt Mikrofilter

4.3. Ecofilt

Mikrofilter

aaWhat does this trademark or name stand

for?

aaEcofilt Mikrofilter is a candle shaped cascade or

multiphase filter. As shown on Fig. 5, it is a candle

shaped filter made of

stainless steel.

aaOwing to its design, this filter is

highly resists to and allows great pressure differences

(deltap) of up to several bars.

aaFiltering surface is cylinder - candle -

shaped wrapped around the base core.

aaThe wrapping has one layer, therefore the

free surface of the filter is set with high precision

(even 98%). Thanks to the

wrapping the shape and size of the slits are also of high

precision, which is between 95-98%. This property gives

highly reliable

and precise separation of filtering surfaces.

aaMicron-gauge wire wrapped around the base

core is also made of stainless steel.

4.3.1. Based on our

experience, we can say that we have designed a robust

candle shaped filter core with low initial resistance,

which can stand great strains, and has a long operating

life of up to 10-15 years.

aaProduction technology in petroleum

industry allows us also to manufacture and/or alter

certain elements of the filter base core

according to the user's specific requests.

aaAs a result, it is now possible to

replace existing filter cores existing housings.

4.3.1.1 The

possibility to change the filtering parameters allows us

to maintain the existing filter surrounding. This leads

to

significant investment cost reduction.

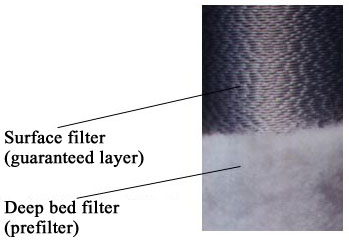

Fig. 6

Prefilter under a microscope

aaPrefilter can be single or multilayered,

which depends on the targeted filtering process goal. By

its adequate positioning and

calibration, it can filtrate and storage large quantities

of impurity.

aaSuch filters then simplify and increase

maintenance level, since they only require replacement of

the deep bed filter.

4.3.2 Our experience has proved that the prefilters

can easily be washed (in suitable solvent); then reused,

and this

process can be repeated several times.

4.3.2.1 These

particular types of cascade filters can be applied to

industries that operate in high temperatures.

4.3.2.2 With the aEcofilt Mikrofilter such influenst, as gas,

steam, liquids, emulsion, etc. can be cleaned with

selected methods.

4.3.2.3 This filter

is highly precise, has a long operating life, gives the

user the possibility to plan its replacement, and has a

remarkable filtering efficiency to 2 µm.

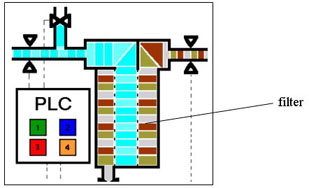

Fig. 7 Filter

unit

aaCascade filters can be cleaned in a few

ways, which are very simple, unless the filtered medium

contains sticky solids.

Fig. 8 Filter

unit for gas injection into underground strorage

4.3.3 Ecofilt Mikrofilter can be supplied with

various control instruments, such as flowmeter, gauge,

velocity meter, etc.

4.3.4 All

information registered by control instruments can be

gathered into a computer data base.

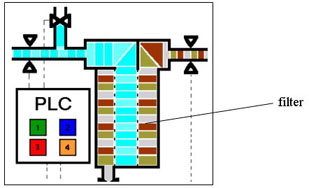

aaWith the support of control instruments

there is only a step towards complete process automation.

Based on required

technical characteristics of the instruments, Ecofilt Mikrofilter allows filtering process

management from PC, by applying PLC.

aaPLC can make daily reports on filtering

process. To analyze and gather instrument information a

PLC can be upgraded

with such software that would include control, correction

and training.

Fig. 9 PLC

4.3.5 Ecofilt Mikrofilter supported filtering unit

can be operated, controlled and cleaned using PLC

control.

4.3.5.1 All

electronic devices are adapted to the existing electronic

surrounding and processes, with which complete accord

and communication is established.

5. Summary

aaEcofilt Mikrofilter is a cascade candle shaped

filter that adapts to existing industrial processes; it

is easy to design and

calibrate, does not require high maintenance, and

eventually can be automated.

aaRobust construction of cake filter made

of stainless steel allows it to be applied to any

industrial environment where the

following is required:

- high filtering standards,

- high accuracy and precision,

- long operating cycle (long maintaining cycle that can

be planned ahead),

- safe operating in emergency situations,

- strict separation,

- long operating life,

- low maintenance costs,

- possibility of automation,

- filtration in abrasive media (gas-steam, liquid,

chemicals, etc.).

aaEcofilt Mikrofilter expands and allows the

possibility to calculate and measure mechanical

filtration without making

additional stress to the medium, and the possibility to

appley effective cleaning and flushing in both domestic

and

industrial environments to up to 2 µm. Reference of its

operation can be seen in Hungary and Serbia and

Mintenegro.

Back to the

News

|